Characteristics and uses of marble, crushing and sand making process

Characteristics and uses of marble, crushing and sand making process

Blog Article

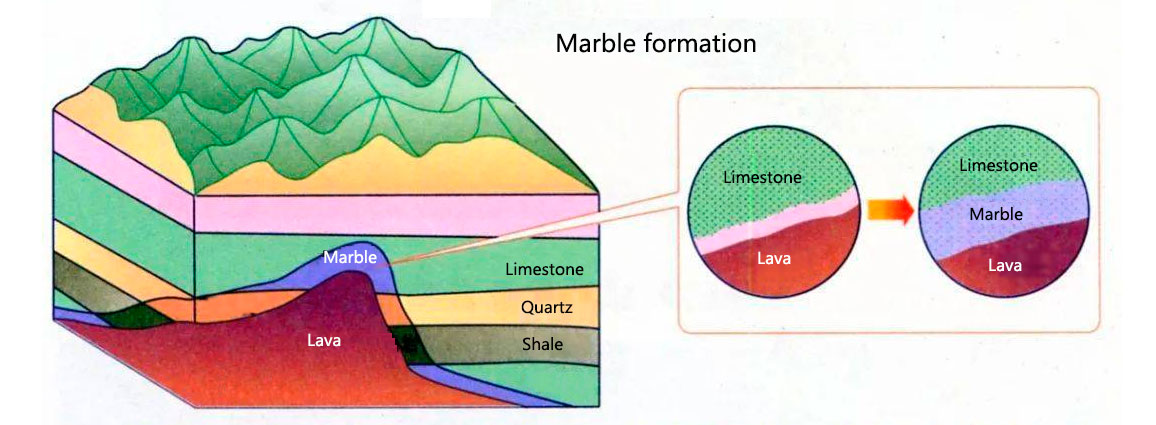

Formation of natural marble

Marble is a natural metamorphic rock. It is made of porous carbonate rock or limestone. After high temperature and high pressure, it undergoes strong extrusion, wrinkling, twisting, fracture, folding and other crystallization processes underground. The mineral composition and organizational structure of the rock are constantly changing. After a long geological evolution, marble, a beautiful natural stone, is formed.

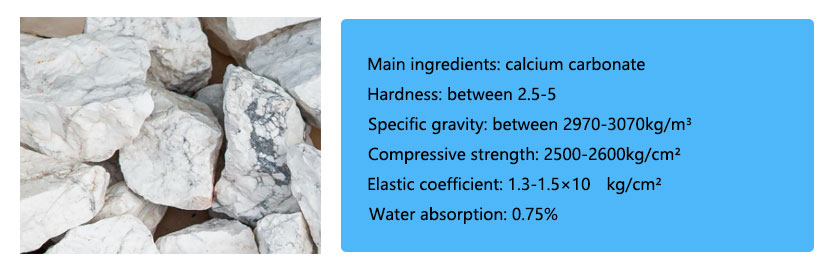

Characteristics of marble

Marble is a hard stone formed by calcium carbonate, composed of limestone, calcite, dolomite and serpentine. The main component is calcium carbonate (accounting for more than 50%). In addition, it also contains calcium oxide, magnesium carbonate, manganese oxide, etc. It has high hardness, high density, and the cut surface presents fine lines and unique crystal structure. Marble has strong plasticity, and its surface gloss and texture are better through grinding and polishing.

Physical properties: Marble is softer than granite, about 2.5-5, with good stability, strong pressure resistance and corrosion resistance, and low water absorption rate not exceeding 0.75%.

Fire resistance: Due to its high calcium carbonate content, it has good fire resistance.

Anti-corrosion performance: Marble is acid- and alkali-resistant and has corrosion resistance in harsh environments. If the surface is waterproofed, it also has certain anti-fouling properties.

Uses of marble

Building decoration: Marble has natural beauty and high-end luxury, and plays an important role in building decoration. It is widely used in floors, walls, columns, sculptures, etc. inside and outside buildings.

Carving and production: Marble has strong plasticity and is widely used in the fields of carving and production and artworks. It is made into various beautiful sculptures and decorations. For example, sculptures in public squares, parks and other places make urban places and buildings more beautiful.

Craft products: Marble has moderate hardness and natural beautiful patterns. It can be processed into crafts and is widely used in jewelry making, home decoration, flower pots and other fields.

Home accessories: The natural beauty and unique texture of marble are also a good choice in home accessories and daily necessities. For example, cabinets, candlesticks, countertops, ornaments, etc. made of marble have a good effect.

Medical equipment: Marble is corrosion-resistant and easy to clean. It is also used in the medical equipment industry. For example, operating tables, knife plates, workbenches, etc. can all be made of marble.

Chemical industry: Calcium carbonate contained in marble is an important raw material for chemical products. Marble powder can also be used to make fillers for plastics, paints, rubber and other products.

Process flow of marble crushing and sand making

Marble has strong compressive resistance, stable chemical properties, wear resistance and corrosion resistance. After processing, it meets the standards for construction use and is a very good raw material for machine-made sand. Then Xingaonai Heavy Industry will take you to understand the equipment and process flow required for marble crushing and sand making production line.

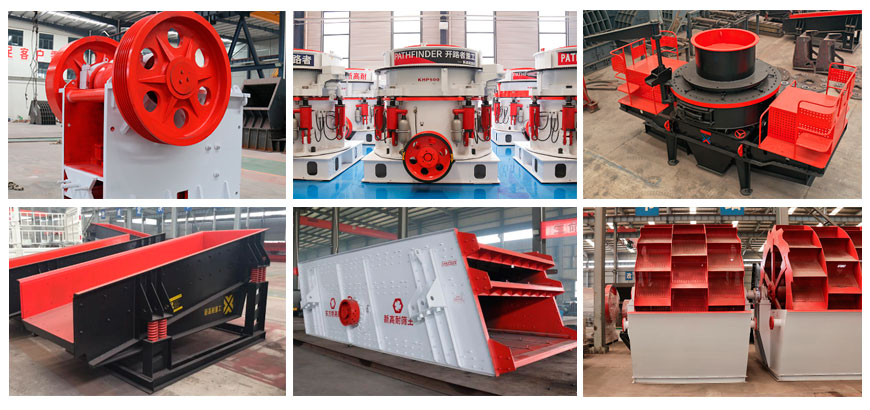

Required equipment

Jaw crusher is used for coarse crushing, Cone Crusher is used for medium and fine crushing, sand making machine is used for shaping sand making, and there are some auxiliary equipment, such as vibrating feeder (feeding equipment), vibrating screen (screening equipment), belt conveyor (conveyor equipment), etc.

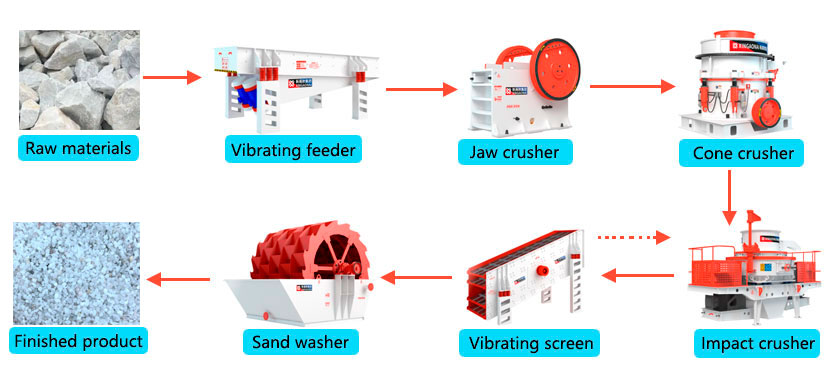

Process flow

Marble materials are evenly transported to the jaw crusher by the vibrating feeder for primary crushing. The crushed materials are then crushed by cone crusher for medium and fine crushing to meet the particle size required by sand making machine. The materials after fine crushing and shaping by sand making machine are screened by vibrating screen. Unqualified materials are returned to sand making machine, and qualified materials are sent to sand washing machine to clean impurities. Finally, the finished products are sent to material storage.

Author:[Xingaonai] Report this page